Contact person:

Ing. Zdenko Hušek, zdenko.husek@mdj.sk, +421 948 376 665

Description of functions/solutions

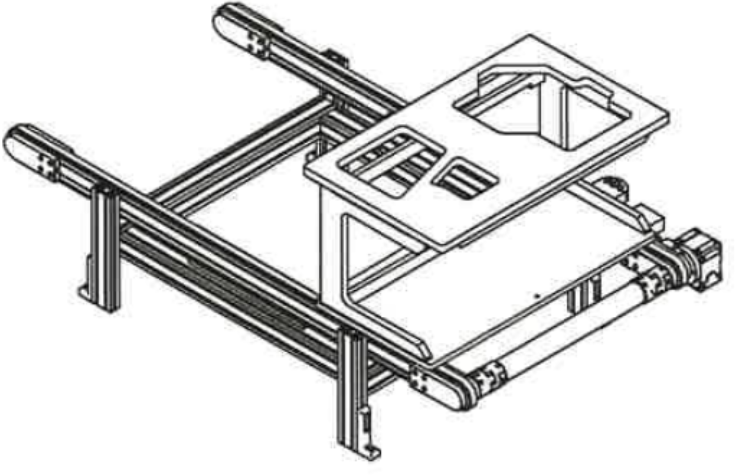

Extension of the existing conveyor with a so-called dead arm, where pallets can be temporarily placed in the event of a full line to compensate for any downtime caused by breakdowns.

Activities carried out

- PLC programming

- HMI programming

- Machine design and implementation

- Electrical design and implementation

Total workplace assembly

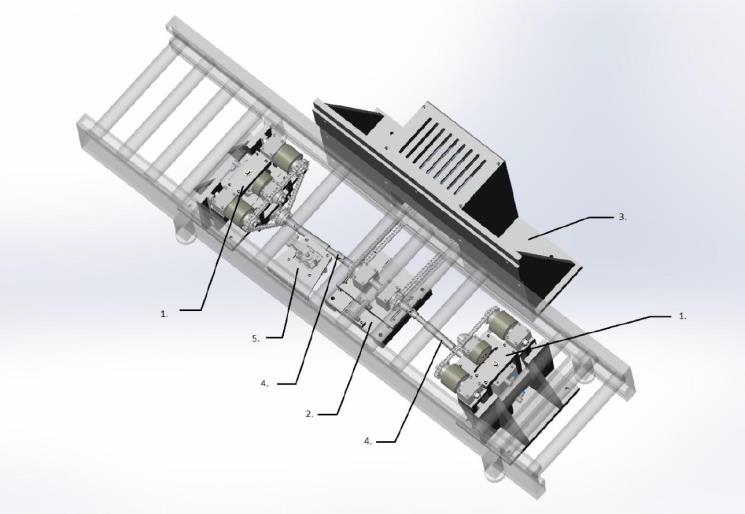

1. lifting mechanism assembly

2. motor chain tensioning assembly

3. motor enclosure assembly

4. extendable cardan shaft

5. pallet tracker assembly

On the main conveyor, there is a designated point from which the pallet can be moved to the dead arm - the operator decides on the move according to the current state and need on the line. When a pallet is moved, it is picked up and moved to the secondary conveyor. 3 pallets can be placed on the conveyor at the same time. If the position in front of the conveyor is empty, the operator can unload the pallet from the tray.