Contact person:

Ing. Dušan Zis, dusan.zis@mdj.sk, +421 905 579 477

Description of functions/solutions

- Selection of control system error messages

- Communication interconnection of control systems

- Communication link of control systems to a higher-level database system

Activities performed

- Analysis of the existing control system and the parent components

- Programme implementation - identification of errors

- Programme implementation - communication interface

DESCRIPTION OF THE SOLUTION

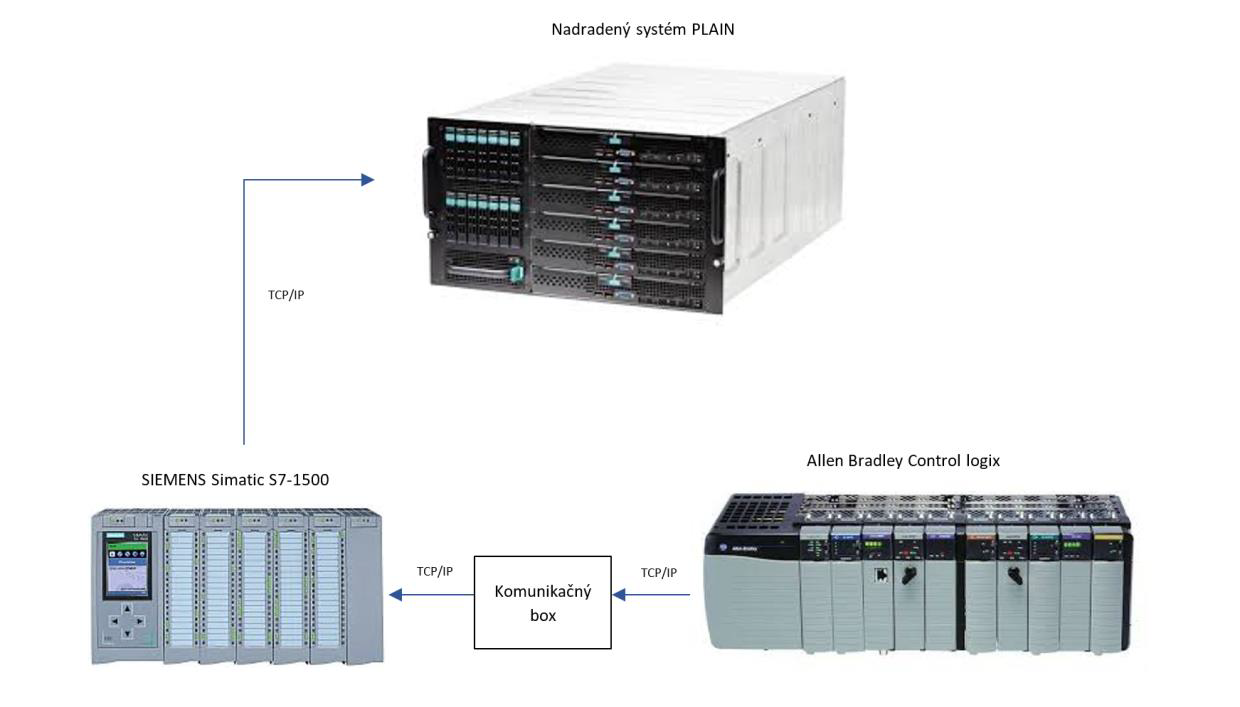

Each line in ESSITY SCA consists of a production and packaging section, which are controlled by separate control systems:

- main line - SIEMENS Simatic S7 1500

- packer - ALLEN Bradley Control Logix

Above the lines, the PLAIN information system is created, which collects information from all lines. Only the control system of the main line is always connected to the PLAIN system.

Reporting collection system implemented:

- aggregate error messages in individual control systems

- establish communication between the main line PLC and the packer - transmission of error messages to the main line:

o communication box - HW interface between Simatic S7 and Allen Bradley - bidirectional TCP/IP

converter (conversion between SIEMENS and Allen Bradley standards)

o the converter can provide bidirectional data exchange between 6 PLCs in one network

- send error messages to the PLAIN system via the TCP/IP interface

APPLICATION AREAS

- Identification of error conditions

- Statistical systems

- Quality evaluation of production processes