Contact person:

Ing. Kvetoslav Molitoris, kvetoslav.molitoris@mdj.sk, +421 907 995 755

Description of functions/solutions

- Automatic registration of finished production (generation of individual numbers)

- Communication with commercial and reference weighing scales

- Operator control via control panels (Siemens)

- Recording of production quality parameters

- Printing of barcodes and selected text parameters on products

- Sending information about finished production to the parent IS (TCP/IP, SQL DB)

- Control system based on Siemens components

- Machine design for guiding product movement to the printer

Activities performed

- Design, implementation and installation of mechanical parts

- Design and implementation of electrical parts and wiring

- PLC programming (control of communication with superior IS)

- Design and implementation of visualization

- Implementation of communication node (between PLC and parent IS)

- Implementation of product barcode marking

DESCRIPTION OF THE SOLUTION

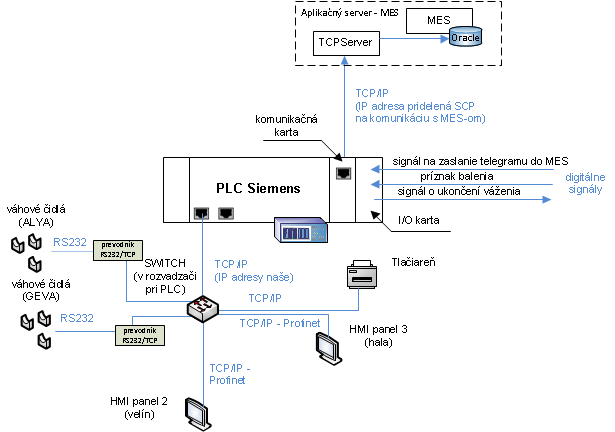

A control system is applied in a pulp bale drying plant. The control system provides communication with two commercial scales. One scale weighs a bale, the other scale weighs a group of six bales (units). The control system further generates a unique number for each unit to which pulp quality data is recorded directly in the control system. A unique barcode is printed on each bale of pulp using contactless technology with a high-resolution barcode and ink suitable for food processing environments. Also included is a TCP/IP communication server that communicates via TCP/IP with the control PLC and sends the data on the produced ounces to the MES master system directly to the SQL database. Two operator panels, one located in the control room and the other directly in the production hall, are used for operator control of the control system. The control system uses Siemens components.

APPLICATION AREAS

- Control systems of production units

- Weighing of materials in the production flow

- Material marking in the production flow

- Communication between the control system and the parent IS

SCHEDULE

Control system (RS) diagram