Contact person:

Ing. Dušan Zis, dusan.zis@mdj.sk, +421 905 579 477

Description of functions/solutions

- Checking the correct number of pieces in the capsule

- Stack quality control - exclusion of crumpled pieces

Activities performed

- Machine design and implementation

- Electrical design and implementation

- Vision systems programming (camera system)

- Programming of the evaluation system

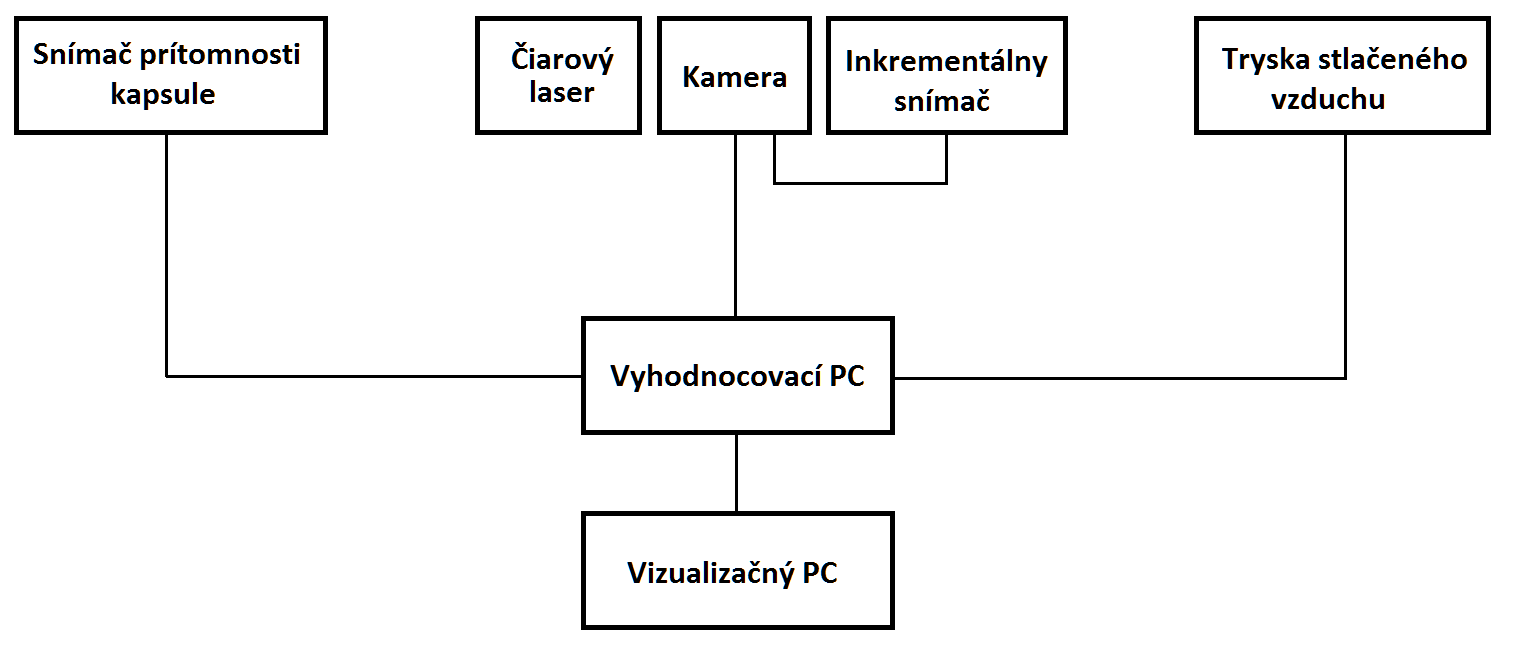

DESCRIPTION OF THE SOLUTION

A line laser illuminates the inserts in the capsules, highlighting their edges. The camera captures an image and evaluates the resulting shapes - determining whether it is an insert or not. It then counts how many shapes in a given image have been evaluated as an insert. For each capsule, a number of images are analysed in this way and a statistical evaluation is used to determine whether the capsule is OK (OK) or has an incorrect number of insertions (NOC). The system is connected to a nozzle that automatically blows the NOK capsules out of the conveyor.

The system also includes two operator programs. The first is used to check the correct position of the camera and laser in case of disassembly/misplacement of any of the components. The second program provides a detailed graphical representation of the evaluation of each capsule, allowing operators to analyze the system's operation and adjust line parameters or train a new product type. The system allows operators to change product parameters/add new products without the need for programmer assistance. The design of the camera and laser mount allows them to be easily disassembled and reassembled to their original position with high precision. The visualization allows changing the range and displays the last evaluated capsule, the last NOK capsule as well as various statistics and system status.

SYSTEM PERFORMANCE

- Production speed: 2.5 capsules per second (real, theoretical maximum may be higher). Can be mounted on both white and black inserts

- Capsule NOK throughput 0%, false NOK < 0.1%

- Total waste < 1% (depends on the specific type and material used)

- Better results (less waste) when using stronger material

- Better results with vertical stacking