Contact person:

Ing. Zdenko Hušek, zdenko.husek@mdj.sk, +421 948 376 665

Description of functions/solutions

The task of the robotic workstation is to determine the position of the profiles, then insert them into the bending machine and move the bent parts to the conveyor for further processing.

A 3D scanner was used to recognize the parts (thanks to the sliding track, it is possible to scan at two positions of the robotic workstation).

In addition to recognizing the position of the part (x, y, z and rotation according to the z-axis), it was also necessary to recognize the parting strips and unload them at a separate location.

Activities performed

- Programming of 3D localization system

- Delivery of hardware

DESCRIPTION OF THE SOLUTION

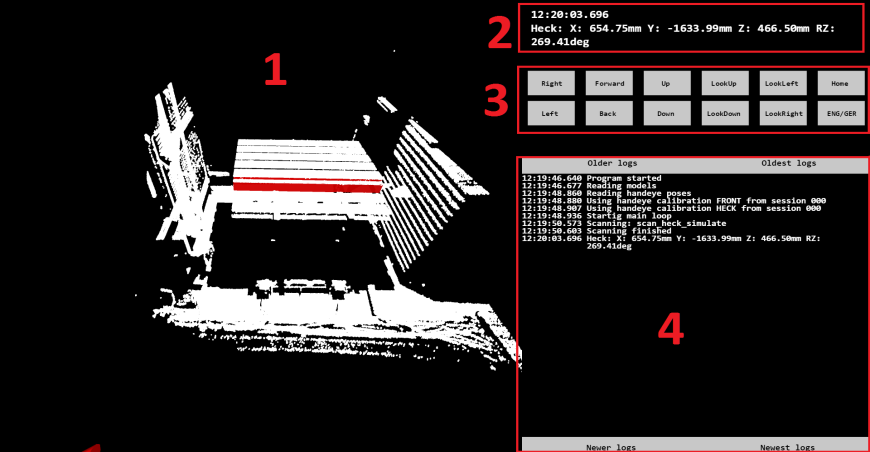

Screen description

1. Visualization (object scan) - used to verify that the profile is in the correct position

2. Status bar - displays information about the system operations performed and also displays any errors that may occur

3. Camera system and its settings - allows the user to see the scanned palette from different angles. It is possible to switch languages (English/German)

4. Logs - show the history of the performed system operations

APPLICATION AREAS

Process automation