Contact person:

Ing. Zdenko Hušek, zdenko.husek@mdj.sk, +421 948 376 665

Description of functions/solutions

The workstation is used to automate and accelerate the bearing assembly process on a robot-operator basis.

Based on a recipe from the database, the workstation determines the parts of the required tolerance for the robot. These parts are automatically dispensed by vibratory feeders. The robot then sequentially deposits them into the bearing housing. The correctness of the bearing composition is checked by a camera system.

Activities performed

- PLC programming

- KUKA robot programming

- Programming of OMRON camera systems

- Machine design and implementation

- Electrical design and implementation

- Communication with database system

DESCRIPTION OF THE SOLUTION

The workstation is used to automate the assembly process of gearboxes (reducers) used for the production of industrial robots. The workstation consists of two separate stations:

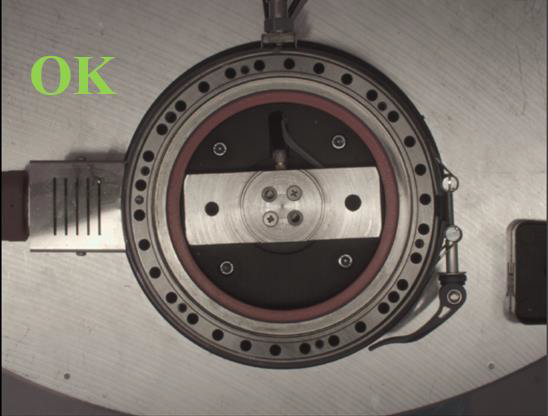

Assembly station

Two different parts of the reducer are assembled in the process. The process starts by reading a barcode, which determines the type of reducer to be assembled and defines the type and quantity of components needed to assemble the gearbox. A turntable is installed within the workstation to allow the robot and operator to work independently. While the robot assembles one part, the operator prepares or completes the next part. A camera control is integrated in the workstation and checks the individual steps and the quality of the folding process.

Screwing and coating station

On the assembled reducers, further operations are performed at a second station, namely applying the sealant, screwing the part and checking the starting torque. All these operations are carried out automatically, the sealant applicator and screwdriver are located on the robot. The results of each operation, the screw tightening torques and the starting torque are entered into a database and paired with the reducer serial number.

APPLICATION AREAS

- Process automation

- Quality control