Contact person:

Ing. Zdenko Hušek, zdenko.husek@mdj.sk, +421 948 376 665

Description of functions/solutions

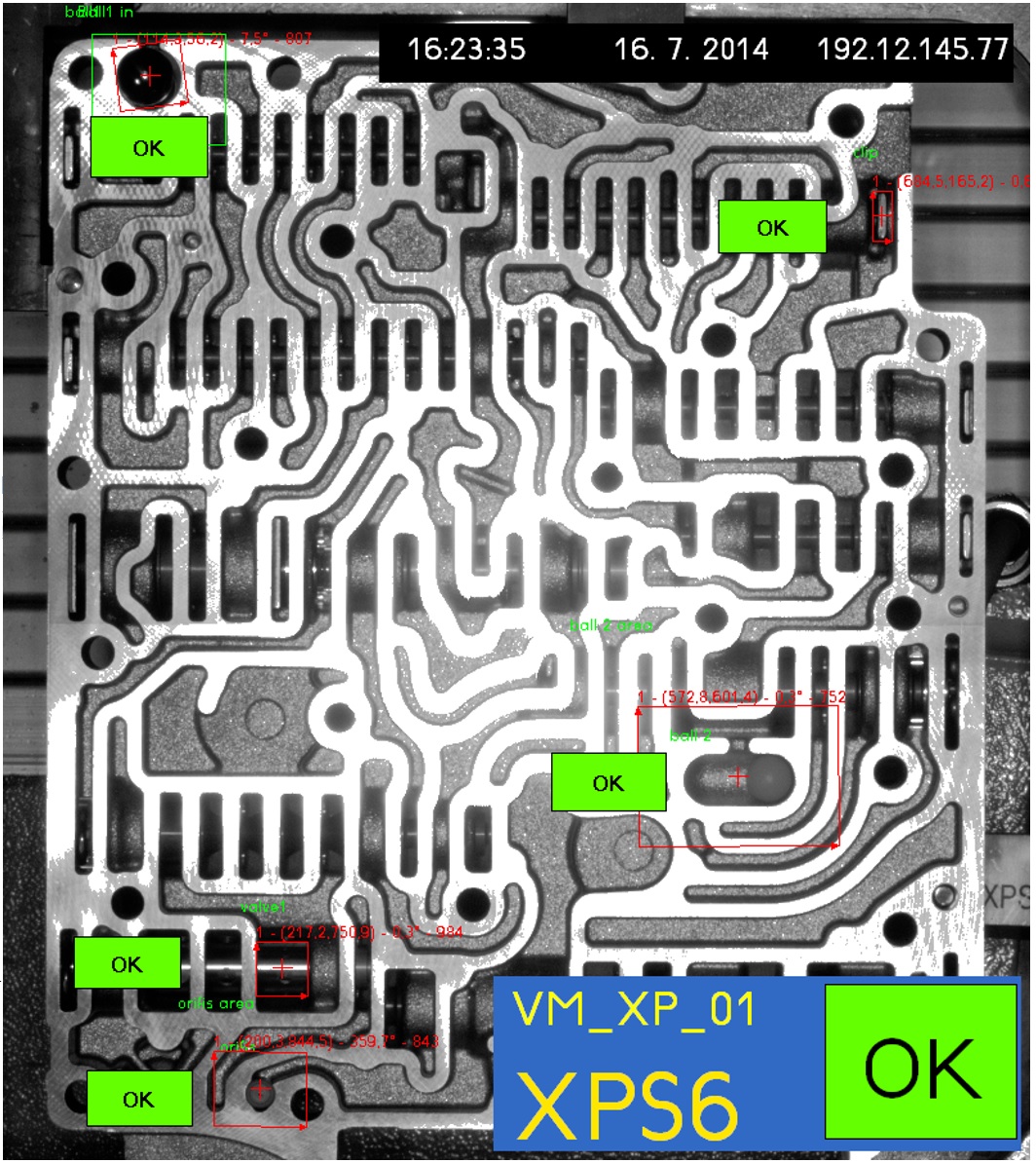

- Camera inspection system installed at eleven workstations on the line

- Check of shaft and wheel type against the selected recipe

Activities performed

- Modification of the PLC control system program

- Modification of the visualisation system

- Programming of cameras

- Assembly activities

DESCRIPTION OF THE SOLUTION

Camera systems were installed at eleven gearbox assembly sites to check the accuracy of the parts being assembled.

The inspection system prevents possible errors in the assembly process by alerting the operator in the event of an error and not allowing the assembly to continue until it is corrected.

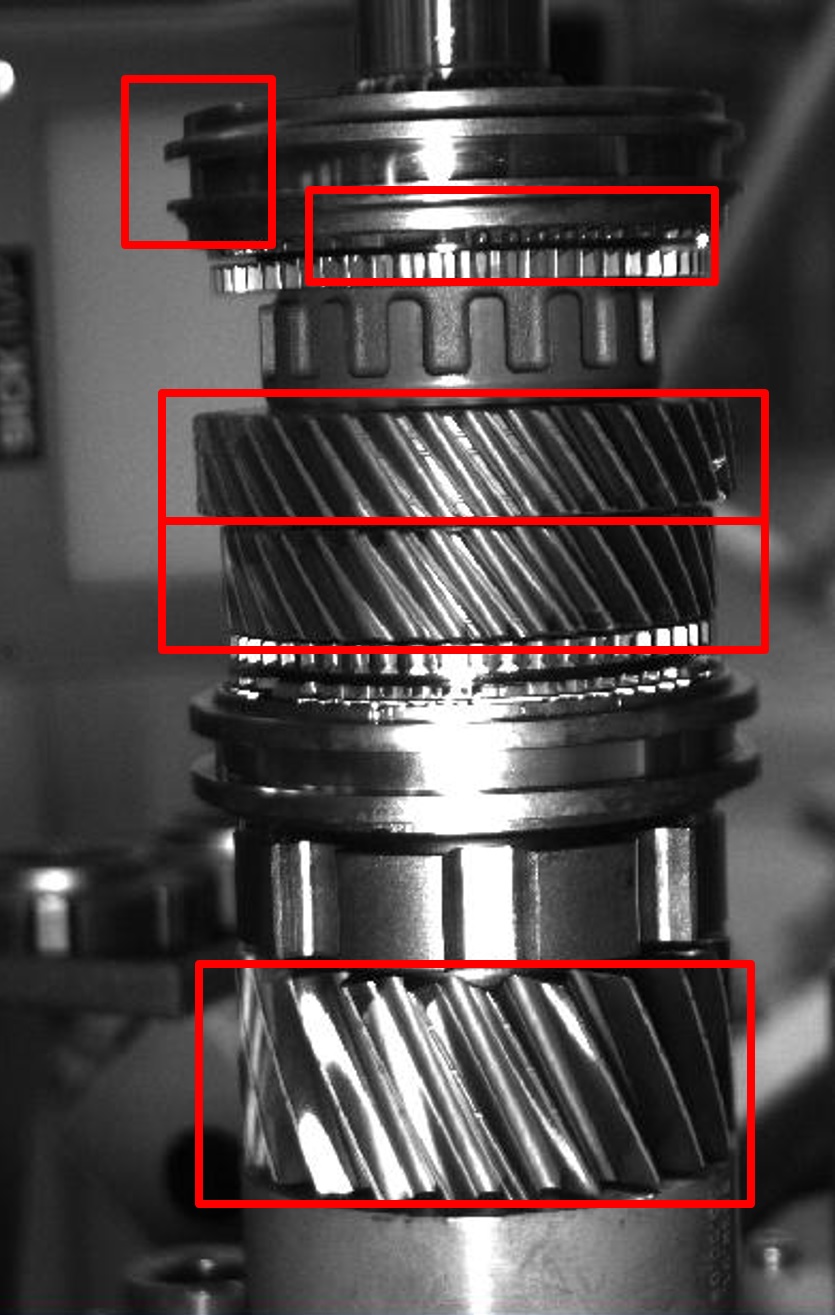

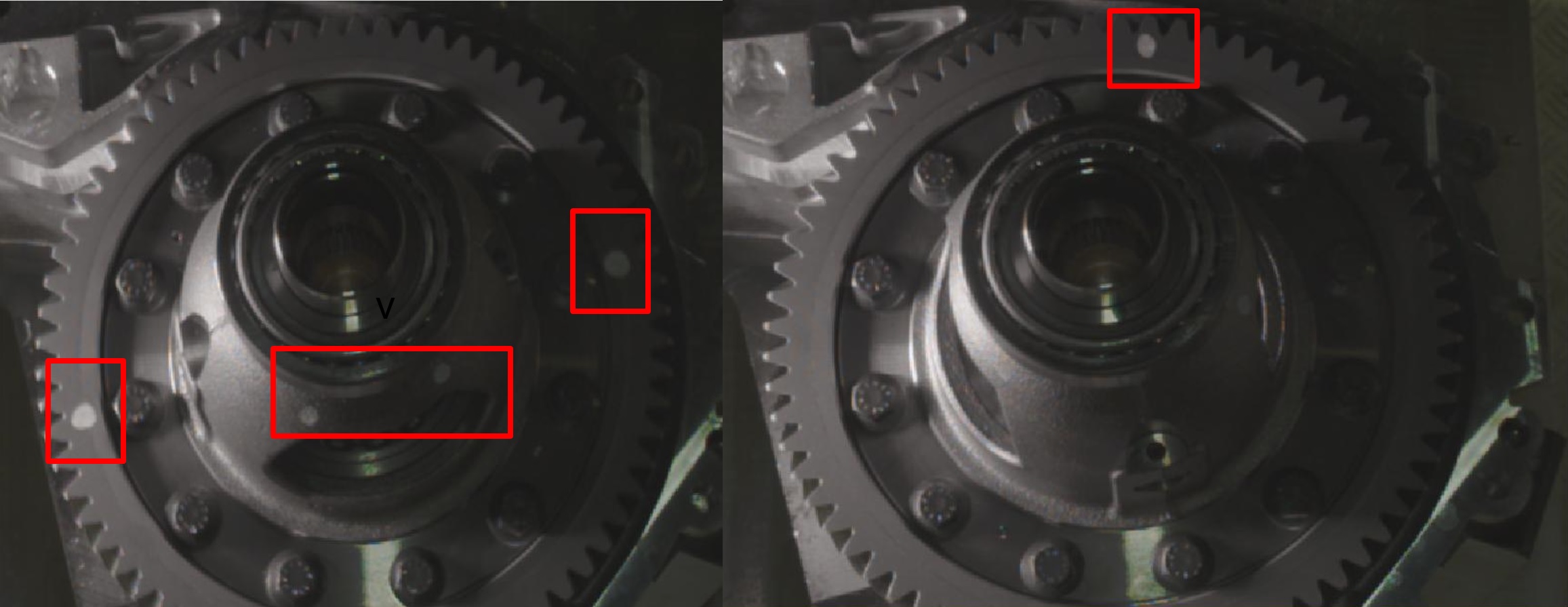

The system detects:

- presence of components

- the correct type of component based on dimensions, splines or presence of dots on the part

- parts that have not undergone a machining process (grinding, sandblasting...)

APPLICATION AREAS

- Automotive

- Quality control

- Assembly inspection

Camera tests