Contact person:

Ing. Ján Liguš, PhD., jan.ligus@mdj.sk, +421 905 622 376

Description of functions/solution

Cleaning of flue gases from waste-to-energy - measures focusing on the combustion process itself, the optimisation of which will rapidly reduce the concentration of CO, TOC and NOx pollutants at the generation stage.

The project deals with the wiring for the individual electrical equipment of the technological parts of the K1 boiler filter from the new K1 filter electrical substation.

Activities performed

- Turnkey analysis and design of electrical parts

- Programming

- Visualization

- Measurement and control (MaR)

- Automated monitoring and control systems and electrical fire alarm systems (AMS and EPS)

DESCRIPTION OF THE SOLUTION

A set of flue gas cleaning technologies to reduce or limit the formation of monitored pollutants. These primary measures are focused on the combustion process itself, the optimisation of which can significantly reduce the concentrations of CO, TOC and NOx pollutants at the generation stage. The reconstruction of the K1 flue gas cleaning plant also focuses on secondary measures, i.e. the modernisation of the plant and the improvement of the efficiency of the flue gas cleaning plant.

The proposed technology for flue gas cleaning of the K1 line enables:

- achieving the concentrations of the monitored pollutants according to the required legal ecological and emission limits (two types of sorbents are used - NaHCO3 and Ca(OH)2)

- the possibility of connecting the flue gases from line K1 to the flue gas cleaning plant of line K2 and vice versa (not at the same time)

- by-pass of the whole technology in case of short-term failure or start-up

APPLICATION AREAS

- Greening in the energy sector - reduction of CO, TOC and NOx emissions at the generation stage

- Energy systems

- Incineration plants

- Boilers for municipal waste

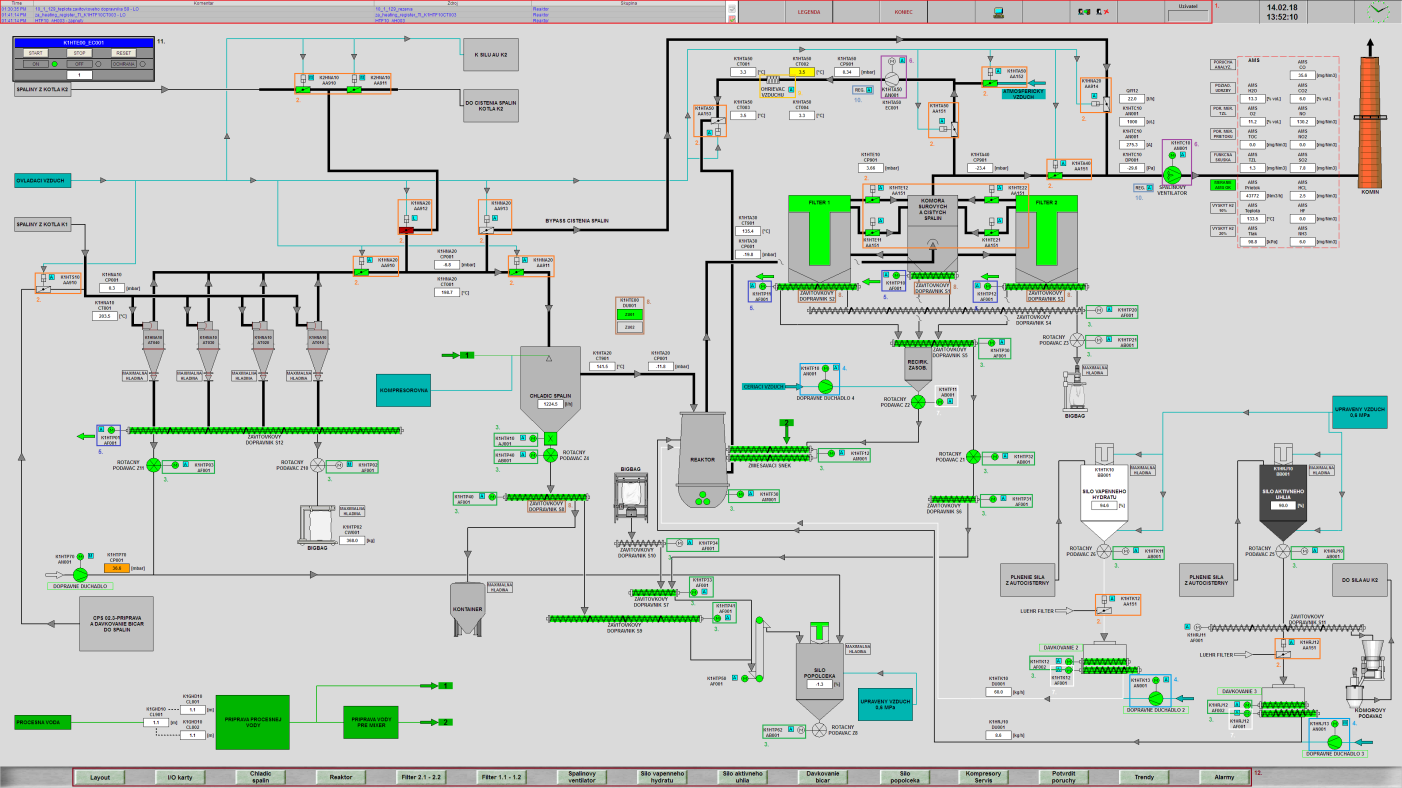

SCHEME

Snapshot of the operator's workstation - main screen

Selected photos from the construction

|