Contact person:

Ing. Dušan Zis, dusan.zis@mdj.sk, +421 905 579 477

Description of functions/solutions

- Addition of the SWL line function - riveting of the shackle in the hook termination for a new reference

- Adaptation of electrical equipment to existing European standards

- Certification of the line - electrical, technology

Activities carried out

- Machine design and implementation

- Turnkey electrical supply

- Programming of the control system

- Visualisation programming Measurement and control (MaR)

DESCRIPTION OF THE SOLUTION

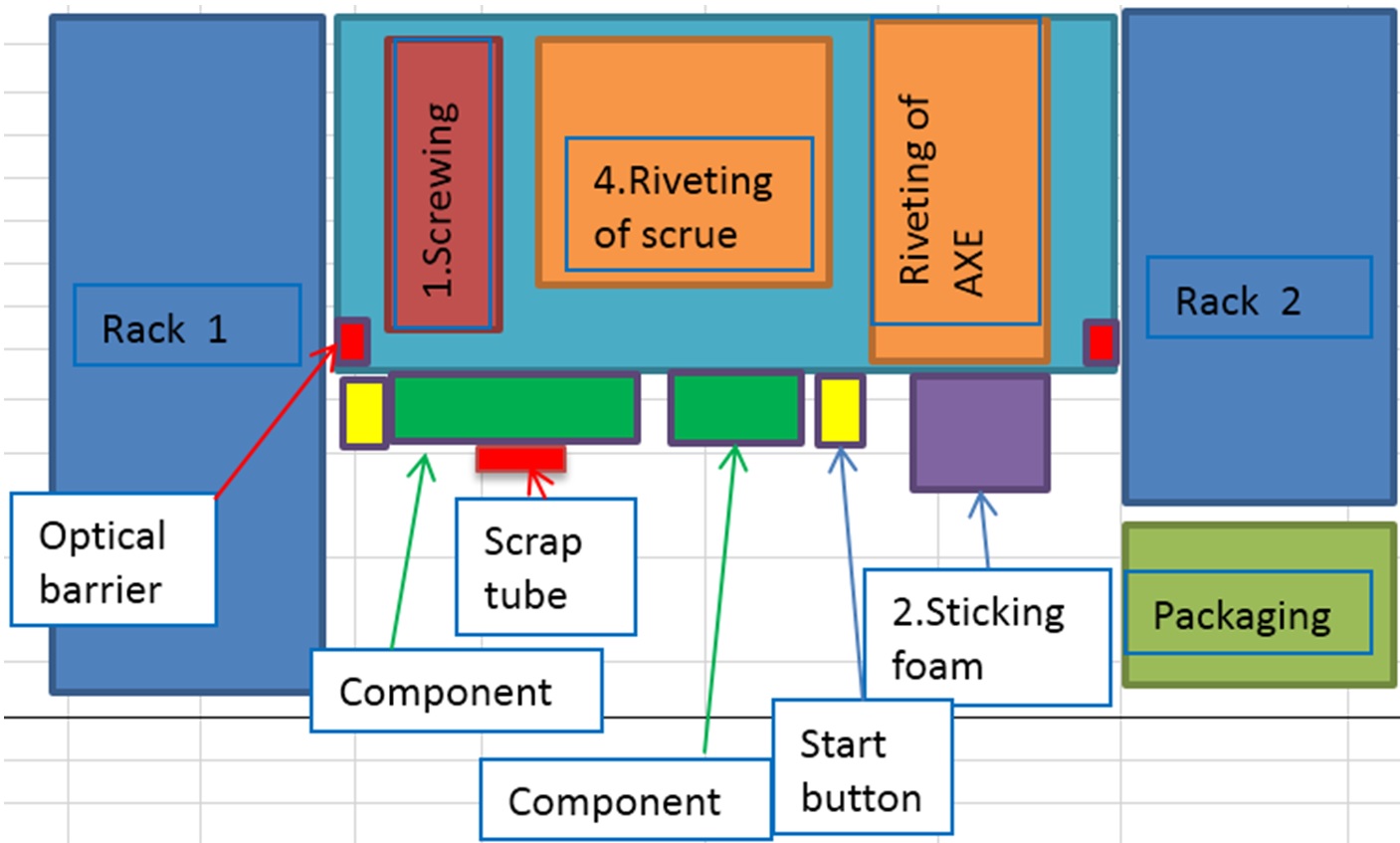

Stand for the production of the required components. The following manufacturing operations are carried out within the stand:

- screwing

- riveting the nut to the bolt

- riveting the axe to the component

The given operations are performed on three different devices placed side by side. The operation of the bench is manual (the worker has to manually place the components into the individual devices) and is carried out with the devices switched off, i.e. the devices do not generate any movements during standard handling in the production environment.

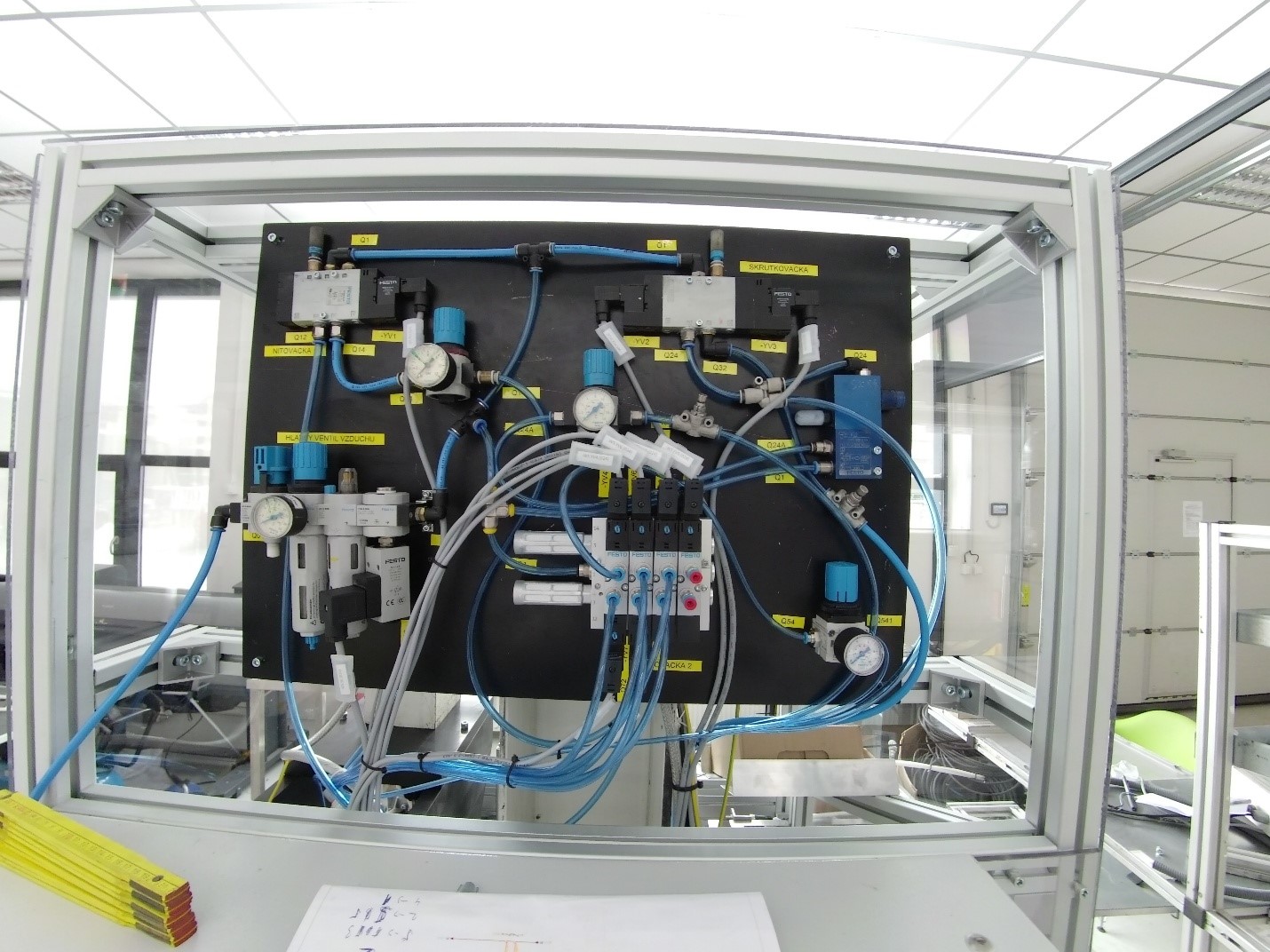

Access to the work area of the production bench is protected by an electronic safety barrier with hand protection with a distance of individual laser beams of 14 mm. The output signal from the safety barrier is connected to a safety relay that switches off the pneumatic circuits. At the same time, the information is also sent to the PLC, which immediately stops the rotary movements generated by the electric motors.

The release of the safety function is confirmed automatically when the barrier break is complete. A central stop button is located above the opening to the operating area, which ensures that all movements are disconnected from the power supply via a safety relay. Unlocking of the central stop is by placing the STOP button in the open position, followed by confirmation of STOP termination via a button on the switchboard display.

SWL line after modification:

SWL total station:

Safety cover:

DESCRIPTION OF THE SCHEME

DESCRIPTION OF THE SCHEME

- Modifications to the SWL line:

o extension of the lower support frame

o modification of the side racks

o addition of riveting station No.2

- Within riveting station No.2, a nest with a gripper was designed to fix the component during riveting. The nest is adjustable in two axes to ensure the desired position of the rivet during riveting. After adjustment, the position of the nest is secured with fixing screws. The nest includes a pneumatic cylinder and a gripper for gripping the rivet

- The overall solution required the construction of a new lower frame, protective covers and racks for the infeed and outfeed components

Safety cover for station:

Safety cover:

Pneumatic Circuits: